Guangdong Zhaogong Technology Co., Ltd

Contact person: Mr. Deng, Miss Que

Tel: 0750-8868298

Mobile: 13676187550, 18022938699

Email: 1679185299@qq.com

Fax: 0750-8868598

Website: www.gdzhaogong.com

Address: No.1 Yadong Road, Chaoyang Industrial Park, Yayao Town, Heshan City, Guangdong Province

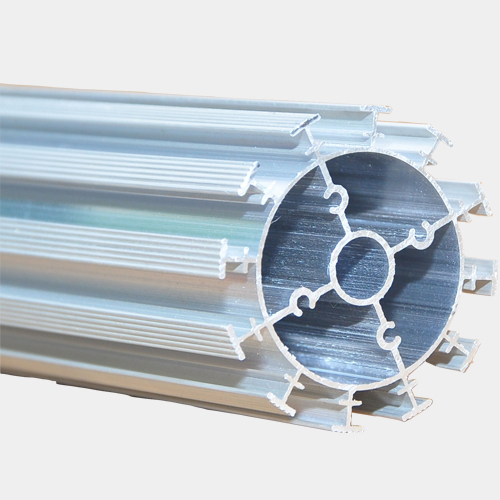

The cold-formed plug-in radiator is a more efficient and compact air-cooled radiator, which is more effective than epoxy bonded plug-in radiators and other combination radiators. It has the following characteristics.

1、 Epoxy bonded finned aluminum radiator

The adhesive fin heat sink does not have the limitations of fin aspect ratio and fin spacing. So far, most inserts are achieved through epoxy adhesive. High thermal conductivity epoxy adhesive is filled at the junction between the fins and the substrate, which does not occupy space or hinder the flow of heat. The thickness of high thermal conductivity epoxy adhesive is usually about 0.13mm, and the impact of thermal resistance is not easily detected in most applications. This manufacturing method can achieve a height to width ratio of 40:1. However, due to manual assembly, the labor cost is high, coupled with the cost of epoxy adhesive, the price of the product is much higher than that of the profile radiator. Through testing, the strength and manufacturing convenience are superior to the production method of epoxy adhesive, and the thermal performance has also been improved.

Both the fins and the substrate are formed with 6063-T5, effectively embedding the fins into the grooves of the substrate. This assembly process integrates the integration of fins and substrate, with good heat bearing performance and unobstructed heat flow output from the substrate. The new all metal embedded heat sink has a 12% higher strength than the epoxy bonded heat sink. The drawing strength of fins in this production process is similar to that of aluminum extruded heat sinks.

2、 Better thermal conductivity

The key to this process lies in the residual air in the bonding area, which forms a barrier that hinders heat flow. The thickness and size of the residual air layer determine the degree of increase in thermal resistance. The high heat concentration in small areas and the high-speed airflow on the cooling surface will amplify the thermal problem at the air junction. The higher heat flow rate that drives the total heat flow leads to temperature differences through a smaller cross-section, and the higher flow rate can reach 3 meters per second, improving the cooling effect but reducing the efficiency of the fins. The effect of reducing fins at higher flow rates is due to the fact that heat travels at a higher rate from the heat source to the cold end of the aluminum radiator, amplifying the thermal resistance of the residual area from the hot edge to the cold edge. At higher wind speeds and high heat flux cooling belts, the high heat flux density can cause the temperature of the radiator to increase by 2-4 ℃

3、 Geometric dimensions of the fin interface

An important aspect of the new cold pressing process is to ensure the precise geometric dimensions of the fins and substrate. Numerous experiments have shown that that shape can eliminate air and tightly fit metal during production assembly. At present, the bonding part of the epoxy adhesive is a rectangular interface, which can achieve bonding strength and exclude air from the bonding area.

Early metal embedded fins opened at the bottom of the substrate's groove. When the fins were assembled into the groove, the flat geometry formed an air sac during the rolling process, which was caused by the mismatch between the two planes during the rolling process.

The new generation of all metal aluminum heat sinks uses a gradually tapered bottom geometric fin, paired with a corresponding substrate groove, to provide many advantages. During the pre deformation process, the fins are positioned correctly and controlled before cold compression deformation, using slight auxiliary support. The cone at the bottom of the fins maintains the fins vertical and parallel, which reduces assembly time and labor costs. During the cold pressing process, the gradually thinning fins at the bottom are precisely matched with the substrate grooves to eliminate air interception. The material between the fins flows meticulously through the root of the fins, mechanically locking the position of the fins and avoiding contamination of the bonding area. The product can be processed like a profile. The innovative process has increased the number of fins and expanded the cooling surface area, with a height to width ratio of 35:1 or even higher

The new all metal heat sink can provide a wide range of dimensions, but like traditional profiles and epoxy bonded heat sinks, there are certain limitations in height, width, and fin density, with the main limitation being the width of the substrate.

4、 Pullout strength

The strength of cold-formed aluminum radiators is increased by 20% compared to adhesive radiators, and there are tighter and more controllable deviations during the processing. The new process design is mainly aimed at reducing costs. Reduced assembly labor and the ability to manufacture standard parts. Achieve this goal. Squeezing the fins does not require additional serration costs. They simplify the manufacturing of customized rib components to increase exposed surface area and generate measurable thermal performance gains.

Guangdong Zhaogong Technology Co., Ltd. is a professional enterprise engaged in research and development, production, and sales of various specifications of aluminum materials, aluminum radiators, and aluminum components. The products are widely used, including the lighting industry, industrial industry, decoration industry, automotive parts, daily necessities, furniture, etc. Honesty and trustworthiness are our service principles. We sincerely welcome domestic and foreign users to come, call, negotiate, and make purchases! Zhaogong Technology: A trustworthy aluminum brand!

(Some of the materials on this website come from the internet. If the information displayed on this website infringes on the intellectual property or other legitimate rights of the media or individuals, please notify us in a timely manner and we will immediately delete it.)

Phone:136-7618-7550 Contact person: Mr. Deng

Mailbox:1679185299@qq.com Fax:0750-8868598

Web:www.gdzhaogong.com

Address: No.1 Yadong Road, Chaoyang Industrial Park, Yayao Town, Heshan City, Guangdong Province

Phone Network WeChat